CNC Machines — End-to-End Localized Solutions by Reliable Brother

As the Indonesian office of TEFU Group, Reliable Brothers provides customers with more convenient and considerate localized services.

As a professional service provider, whether you are putting a production line into operation, building a new factory, or adding a single piece of equipment to meet production needs, we can provide you with professional and suitable machine tools and equipment to minimize your selection risk. We provide a trial cutting mailing service to provide you with a reference for purchasing machines with more confidence. Rich application experience in the processing industry can provide valuable insights and help you avoid detours.

company advantage

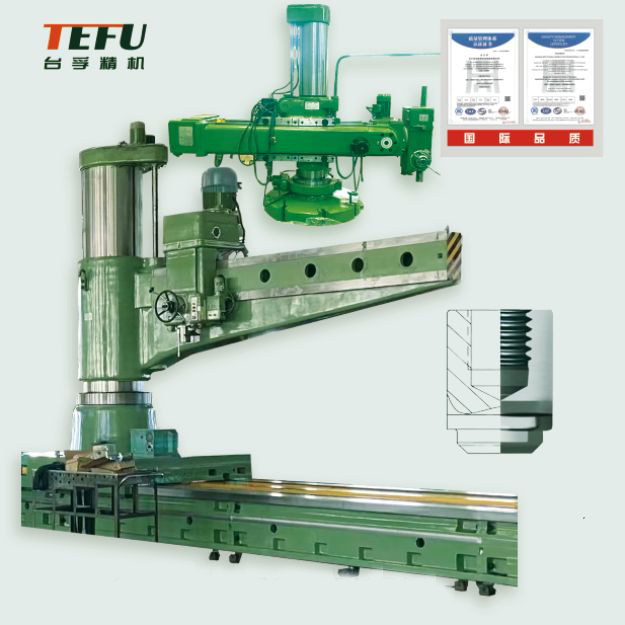

After three years of hands-on training by Zhongjie Boring and Drilling Machine Factory from 2009 to 2011, TEFU has fully inherited the processing machines, production processes, inspection technologies, and all technical personnel, making us China’s largest radial drilling machine manufacturer.

All core components and parts are produced in our factory to avoid the uncontrollable quality of outsourcing processing. We have the processing and production capacity for all specifications below 125MM diameter radial drilling machines and the production capacity for modified radial drilling machines.

Product quality comes from production, not inspection. After repeated inspections by users worldwide for no less than 35 years, it has long been a business card that represents the quality of our machine tool manufacturing. Product quality is our life. Through strict inspection technology and strict control of each production link, our products have always been the best quality radial drilling machines in China.

As a senior team engaged in after-sales service for many years, we have been serving Chinese customers since 2007 and deeply understand customers’ production. Now we come to Indonesia to provide you with more convenient door-to-door maintenance services, and timely installation services, and strive to improve the supply of accessories to solve your troubles in a timely manner.

Featured Products

The arm drilling machine is a professional machine tool for drilling and tapping, especially suitable for drilling single pieces and small batches of parts. It is widely used in engineering machinery, molds, steel structures, and assembly factories. The maximum drilling diameter ranges from 40 to 125 mm. If the stroke requirement is larger, a modified radial drill can be used for processing.

Complex long-stroke drilling is a very economical choice. The radial drilling machine is recommended for multi-angle drilling

Turning, small lathes, CNC lathes, vertical lathes, etc. Precision stability

A full range of small and medium-sized lathes with very high-cost performance. Focusing on product research and development, key technology manufacturing, product assembly, debugging and testing, and advanced production management concepts, the products are sold all over the world with a series of advantages such as high-speed processing mode, high-precision control function, and efficient processing performance.

The overall design is optimized for high-rigidity machining centers, especially suitable for mold production, large cutting force, and more efficient roughing.

The real mechanical processing automation production line is a good choice to meet the needs of continuous mass production day and night. It provides an overall solution for the mechanical processing automation production line, breaks through the bottlenecks of the two major industries, takes the lead in providing customers with an integrated solution for the manufacturing of mechanical parts, and provides a complete solution for the entire production line layout.

Boring and milling machines can be broadly categorized into four types based on load-bearing capacity: small-sized boring and milling machines, large-sized boring and milling machines, floor-type boring and milling machines, and double-ended boring and milling machines.

Customized production and processing of non-standard small hardware parts. Produce according to drawings and then send them from Chinese factories.

Industrial Equipment Business Classification

- Machine tools

- Machining Automation

- automated warehouse

- Casting equipment

- 3D printing equipment

- Non-ferrous welding

Machine tools

Just provide me with a drawing or blank, and we can design the machine required for the entire process. The machine selected is of first-class quality or first-class cost performance.

Machining Automation

Mass production parts factory can create value for you day and night, and will not cause quality problems due to personnel changes. You can choose an automatic machining production line.

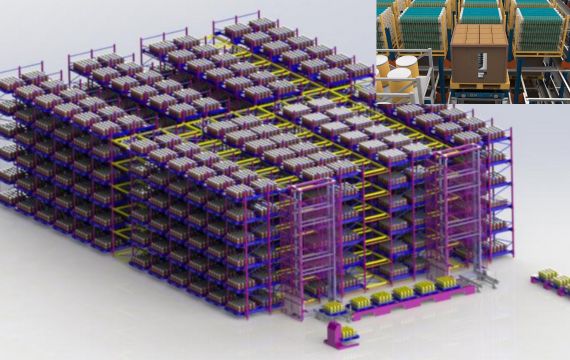

automated warehouse

Cargo warehousing, or cold storage, will improve your delivery accuracy and cargo turnover rate, allowing you to double your storage capacity in the same area.

Casting equipment

High-end casting equipment improves quality and added value makes more money, and is a necessary upgrade solution for the casting industry.

3D printing equipment

A world-class machine for quickly printing sand molds and sand cores for casting, improving the efficiency of sand casting. Printing and mold services create value for foundries.

Non-ferrous welding

High-performance nonferrous welding materials, bus alloys, and production welding materials, welding equipment solutions.

Industry Applications

Frequently Asked Questions

The equipment quality usually has a 1-year warranty period. If there is a failure during the warranty period, the accessories and repairs are free. The service in the second year is free, but the accessories need to be paid for.

We have carefully selected the equipment in the industry, all of which are cost-effective in China or are leading products in the industry. The quality is strictly guaranteed. All products have been carefully inspected in the factory. Please feel free to use them.

You can contact us at any time. We can come to your factory at your convenience to understand the situation and tailor a specific plan. You can also send us drawings and photos first and make suggestions remotely.

For existing equipment, we can usually provide product sample production services, or processing services for similar equipment. After processing, it will be mailed from China.

After understanding the equipment in your factory, we will recommend suitable equipment for you, and even plan and design the whole workshop or industrial park.

Get an Instant Quote

-

What is the 3D printing sand mold service? For the drawing production service, you provide the drawings, and we are responsible for using 3D printing technology to produce casting sand molds and sand cores for you, shortening your early sample production speed. For sand mold production, you only need to take the sand mold and continue to the next step. Or you also need to buy such a machine to make it yourself.

Lorem IpsumSimply Dummy Text

Lorem IpsumSimply Dummy Text -

How can we cooperate in welding business? We can understand the welding situation in your factory and match the appropriate welding materials or welding equipment according to your needs.

Lorem IpsumSimply Dummy Text

Lorem IpsumSimply Dummy Text